The Great War Centenary

1917 - ExhibitionBoomtown - From

Front Line to White Lund

Lancaster’s war time production

As the British Army expanded in size - to more than 5 million men -

the need for military supplies, equipment, arms and munitions quickly

saw existing suppliers unable to cope with the demand. As the war

progressed more and more factories were built and many existing

businesses changed their output to meet the needs.

Lancaster was no different from many towns up and down the country. Two

massive factories were specially constructed to supply munitions and

existing works switched their production in support of the war effort.

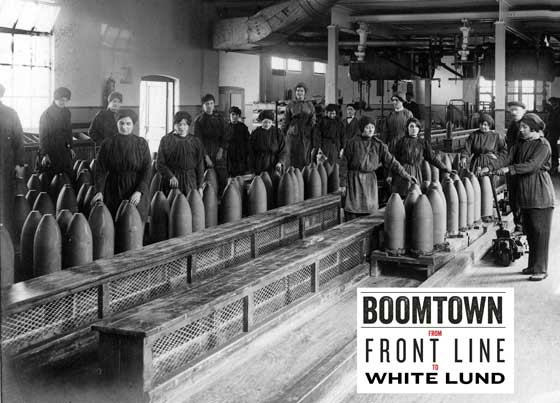

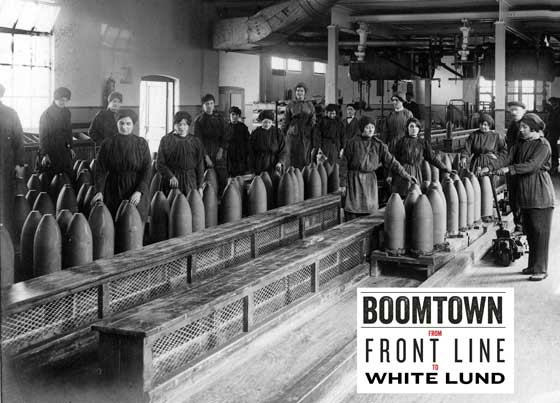

National Projectile Factory

This new factory was built between Caton Road and the Midland Railway’s

line to Leeds via the Lune Valley. It was well served by all forms of

transport, including Lancaster’s canal (used for coal supplies) that

formed its northern boundary. Construction work started on 11th

September 1915 and production started on 5th March 1916 even though

building work was not finished until November.

Although Vickers Ltd of Barrow ran the enterprise, the local council

agreed to major improvements to that part of the town including laying a

new gas main, extending the bus route along Caton Road and even offering

discounted access for staff to the public baths and for team sports on

Giant Axe Field. The factory was designed to produce 6,000 6 inch,

3,500 9.2 inch and 6,000 60-pound shell cases a week. These were shipped

out and many found their way to their sister factory on White Lund. In

1917 the Projectile Factory took in guns for repair alongside its shell

case production.

Number 13 National Filling Factory

The Filling Factory site was well chosen with good communication routes

between to and from Lancaster and Morecambe. At the same time it was a

reasonable distance from both centres of population. The massive works,

at White Lund, feature in the next gallery.

Caton Engineering Works

The disused Wagon & Carriage Works on Caton Road had ceased production

in 1908. It had been used as an Internment Camp for German, Austrian and

Turkish ‘aliens’ in 1914-15, before being taken over for the war effort.

Caton Engineering Works was established, with much secrecy, by the

Vickers and Armstrong Companies to produce torpedoes. The works employed

large numbers of women including many doing precision tooling work, to

produce both the Mark VIII 18 inch torpedo and the Mark II 21 inch

torpedo. Production, at the end of 1917, rose to 22 torpedoes a week,

with the total produced by the end of the war being noted as 1,726.

Many of Lancaster’s existing firms answered the call, changing or

adapting production in their factories. Examples include:

The Lune Valley Engineering Company manufactured military field

cookers, not only for the British military, but also for other counties.

Each field cooker could provide enough stewed, boiled, baked or fried

food for 350 men at one time. These field cookers were used in

Gallipoli, Egypt, Mesopotamia, India and the Western Front in France and

Belgium.

William Goodacre and Sons Ltd produced a range of matting for

warship decks, field gun protectors and hospital ships at their Albion

Mills works. They also made various types of screening and camouflage

work at their looms.

Storeys Brothers bought in machinery to make shells and, by

February 1916, it was noted (and described as) ‘the munitions factory at

White Cross had been added to the list of Works controlled by the

Government’. In line with a number of businesses, Storey Brothers began

a weekly contribution to wives and dependents of men ‘at the front’.

Noting that foodstuffs were getting in short supply (before rationing

was introduced), the company introduced a yearly bonus to help offset

the rise in prices.

Williamsons of Lancaster continued to produce its key product,

linoleum. Although it did not become one of the Government controlled

factories its products were vital for the war effort. As their floor

coverings were easy to clean and disinfect it was in great demand from

hospitals, the Red Cross, convalescent homes and the like. This business

also paid an allowance to the families of their workmen serving in the

forces. They also started employing women in roles that had been

exclusively for men, as the workforce enlisted and were later

conscripted. In 1916, for example, of the 473 new staff taken on at

Williamsons just over 87% (414) were women. Their wages never matched

their male colleagues and, at 14 shillings (70p) a week, were around

half those of munitions girls at White Lund.

Waring and Gillow Ltd, Lancaster’s famous furniture business of

Gillows and Co dated back to the early 18th century. By the early years

of the 20th century it had merged with the Liverpool based company of

Waring. They produced a wide range of items for the war effort using the

full range of skills found across each department. This ranged from

standard joinery for packing crates, fine woodworking for aeroplane

wings and upholstery for tents, haversacks and even ‘serge tunics and

knickers for Indian troops’.

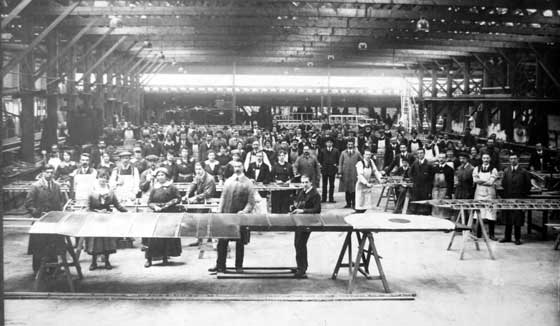

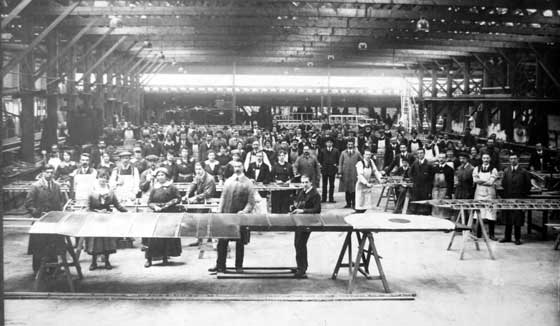

Waring and Gillow Ltd

Aircraft Work

Aircraft wing production at Waring & Gillows, Lancaster

Accession Number: LM74-86-2

Many components were manufactured for the DH9 aircraft.

Aeroplane wings

Aeroplane propellers

Centres

Tails

Struts

Engine beddings

Fuselage

Ailerons – the hinged wing flap that controlled the ‘roll’ of an

aeroplane

Waring and Gillow Ltd

General Work

Of this varied assortment of articles the firm were responsible for a

total output of 338,755

Tables

Ammunition Boxes

Bedsteads

Forms

Poles

Instrument Cases

Mule ammunition carriers

Nosebags

Machine gun cartridge belts

Water buckets

Pom-pom cartridge belts

Lewis gun ammunition carriers

Kit bags

Valises

Gun breech covers

Waterproof gun cotton bags

Bolsters

Rifle slings

Mosquito head covers

Mosquito net tents

Serge Tunics

Knickers for Indian Troops

Ordinary Tents

Gas mask haversacks

Rifle bolt covers

One-man tents

Munition workers caps

Haversacks

Horse water buckets

Horse rugs

Marquees

‘Housewives’ – a small fabric pouch for soldiers’ sewing essentials

(thimble, thread, spare buttons etc) to darn or repair uniforms

© Images are copyright, Trustees of the King's Own Royal Regiment Museum.

You must seek permission prior to

publication of any of our images.

Only a proportion of our collections

are on display at anyone time. Certain items are on loan for display

in other institutions. An appointment is required to consult any of

our collections which are held in store.